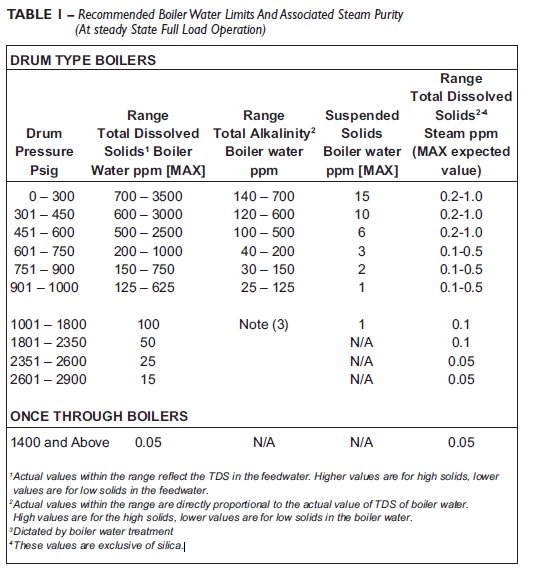

Boiler water parameters upto 20 kg cm2 21 kg cm2to 39 kg cm2 40kg cm2 59kg cm2 unit total hardness not detectable not detectable not detectable total alkalinity 700 500 300 as ppm caco 3 caustic alkalinity 350 200 60 as ppm caco 3 ph value 11 0 o 12 0 11 to 12 10 5 to 11 0 residual sodium sulphite 30 to 50 20 to 30 ppm as na 2so 3.

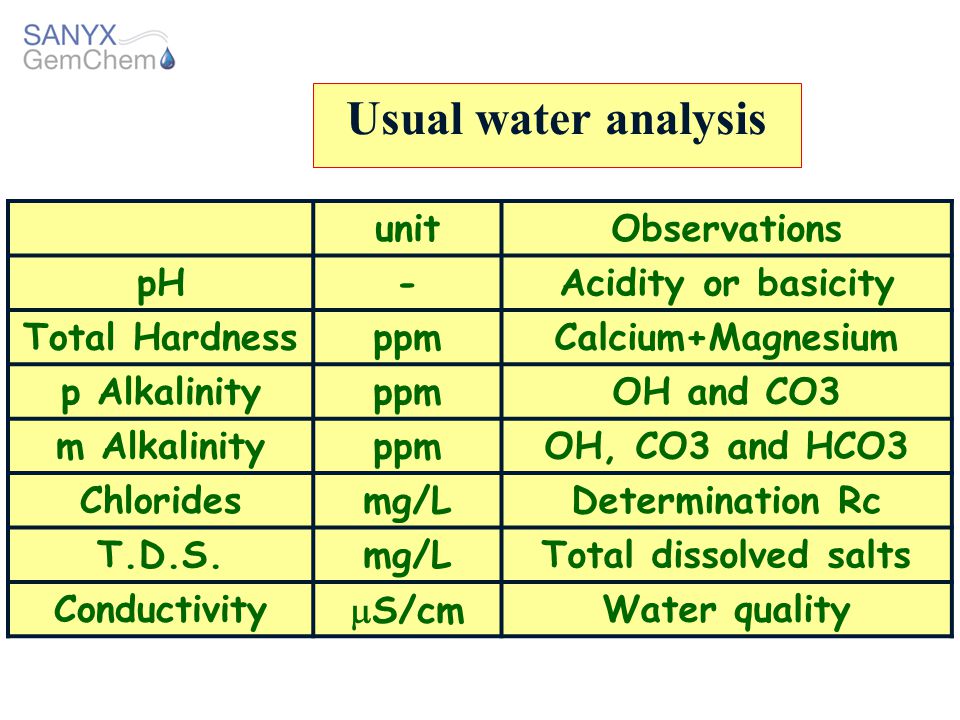

Boiler water hardness ppm.

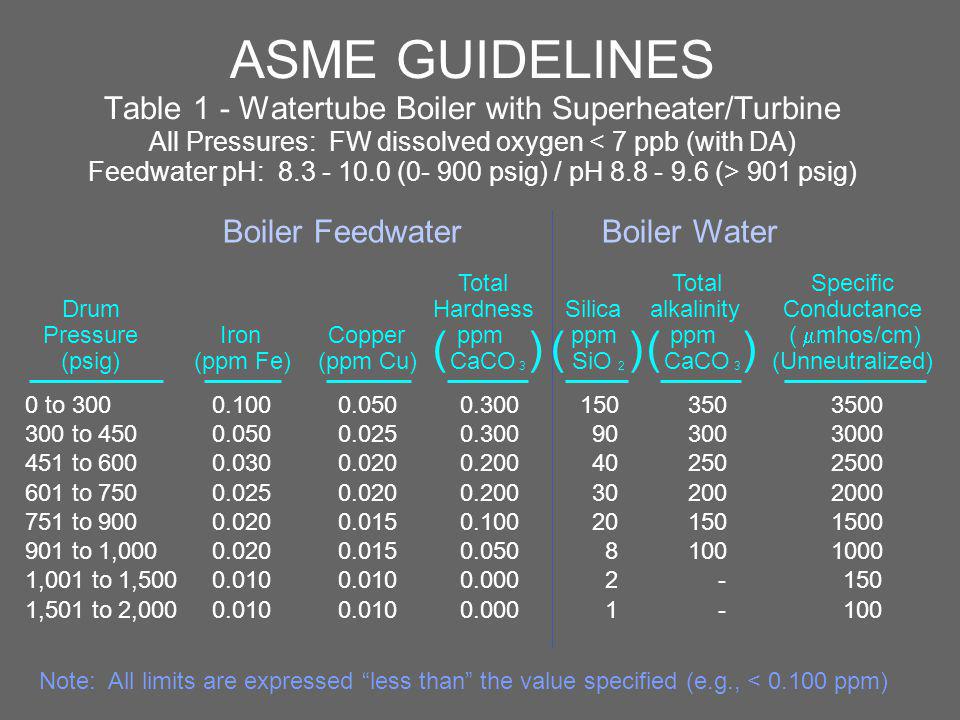

The below table is the total dissolved solids or tds alkalinity and hardness versus boiler pressure.

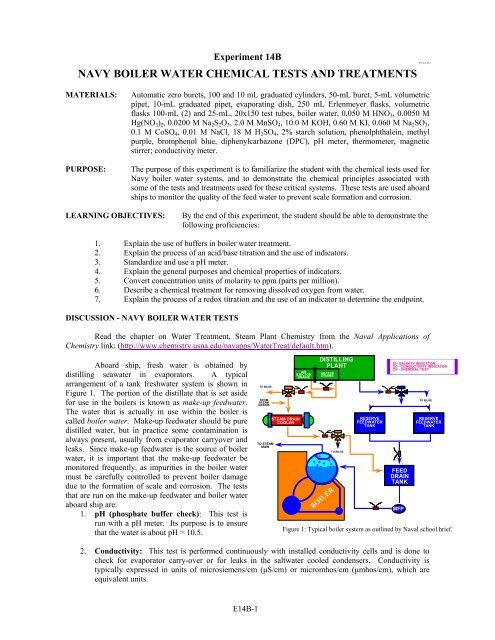

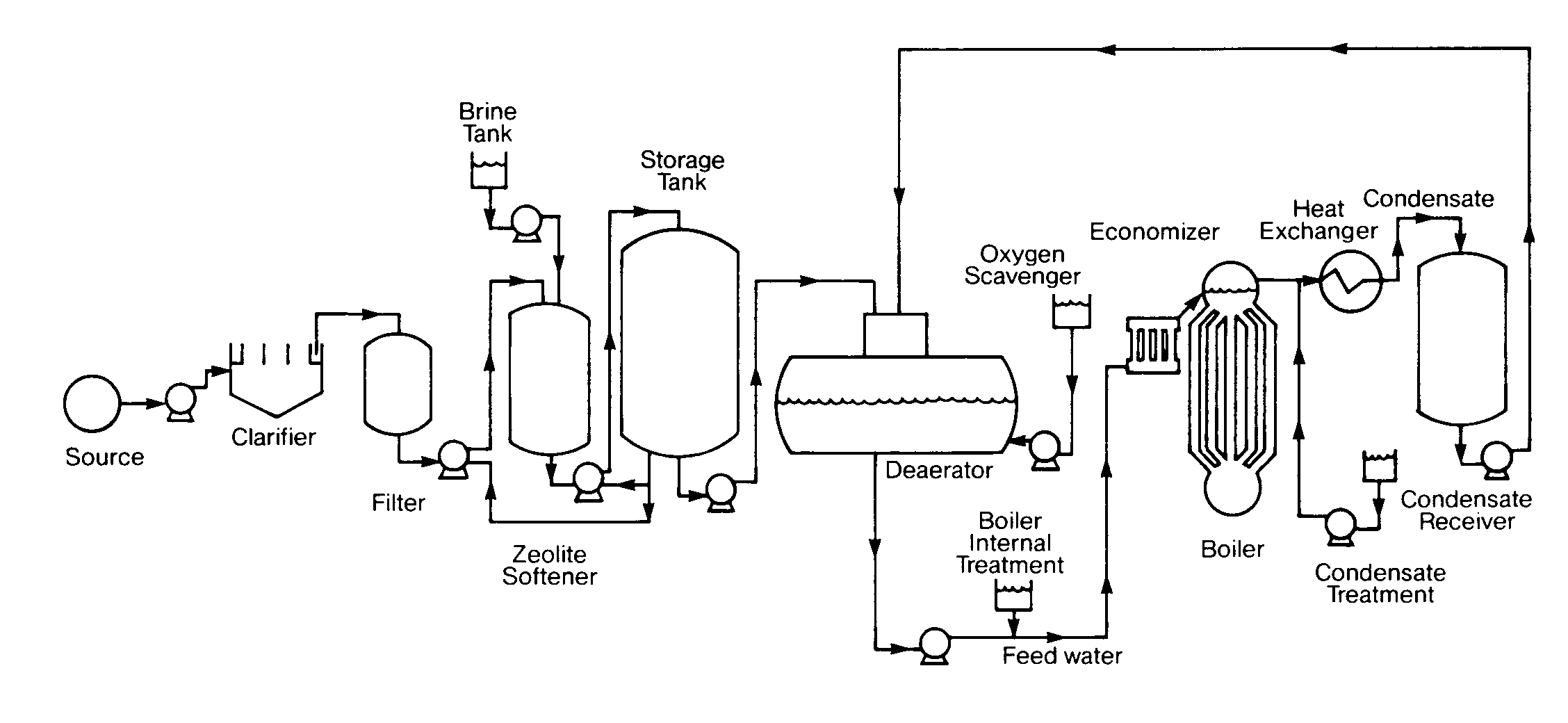

Therefore good internal boiler water treatment programs are necessary.

Boiler water quality boiler chemicals are used to ensure proper boiler water quality in boilers.

Presented by cleaver brooks steve connor bill hooke.

General guidelines to prevent corrosion and scaling in low pressure boilers are as follows.

Free oh alkalinity 200 400 ppm.

Ph 8 3 10 0.

Total alkalinity 700 ppm.

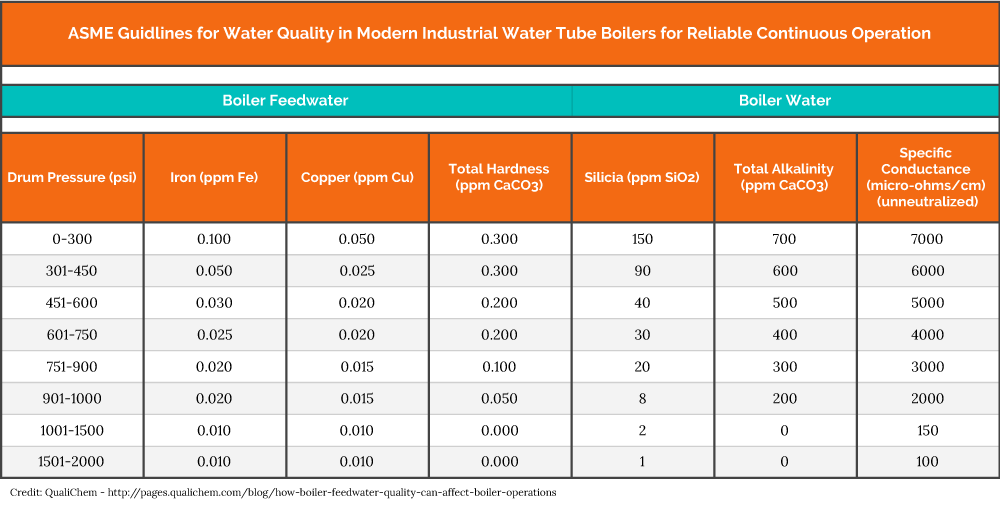

Total silica 150 ppm maximum.

A boiler that makes up 4000 gal day of water having 100 ppm of hardness has a potential of accumulating over 1000 pounds of scale per year.

Non volatile toc 1 ppm.

For boiler water however a hydrometer can be used to obtain an approximate measurement of the dissolved solids since for boiler water each increase of 0 000 1 relative density at 15 5 c is approximately equal to 110 ppm.

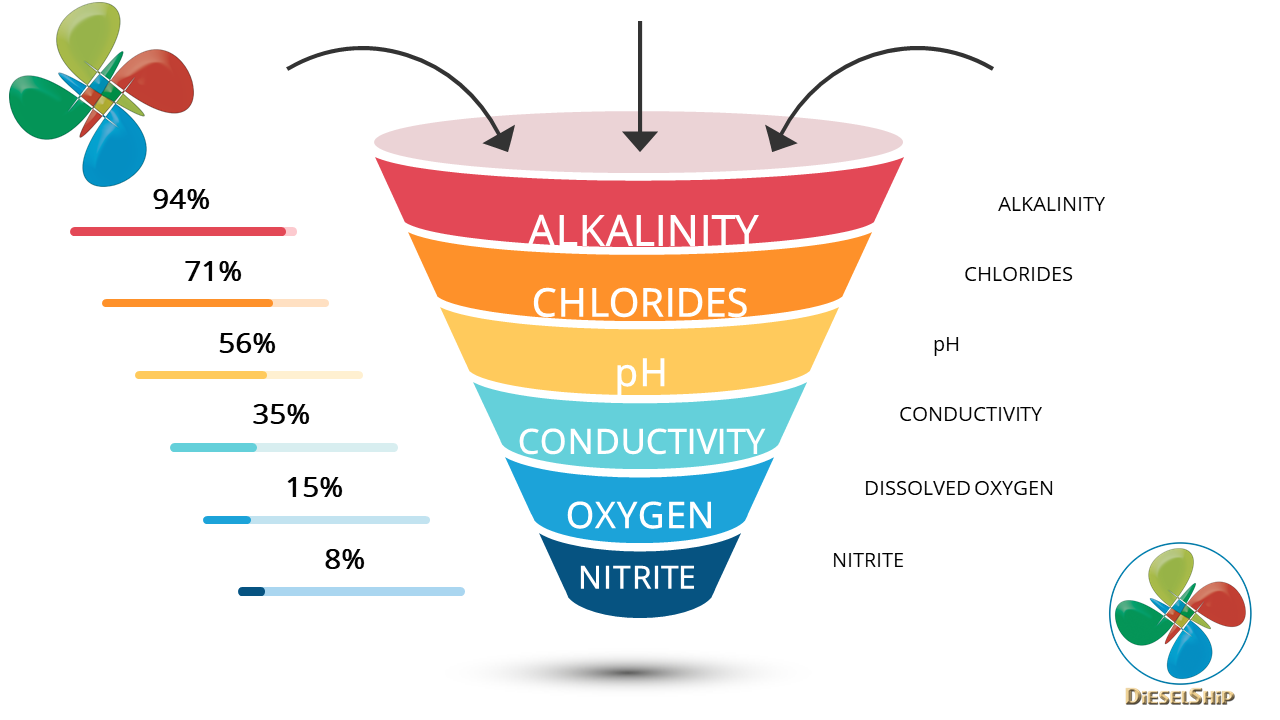

In treated waters alkalinity may also be contributed by hydroxide phosphate silicate and.

It is desirable to keep the concentration of phosphates in the water to 30 50 ppm in order for complete reaction of the phosphates with the calcium hardness entering the boiler through the feedwater.

Alkalinity test in natural waters alkalinity is most commonly the result of bicarbonate and carbonate ions.

Scale is a buildup of solid material formed on internal boiler surfaces.

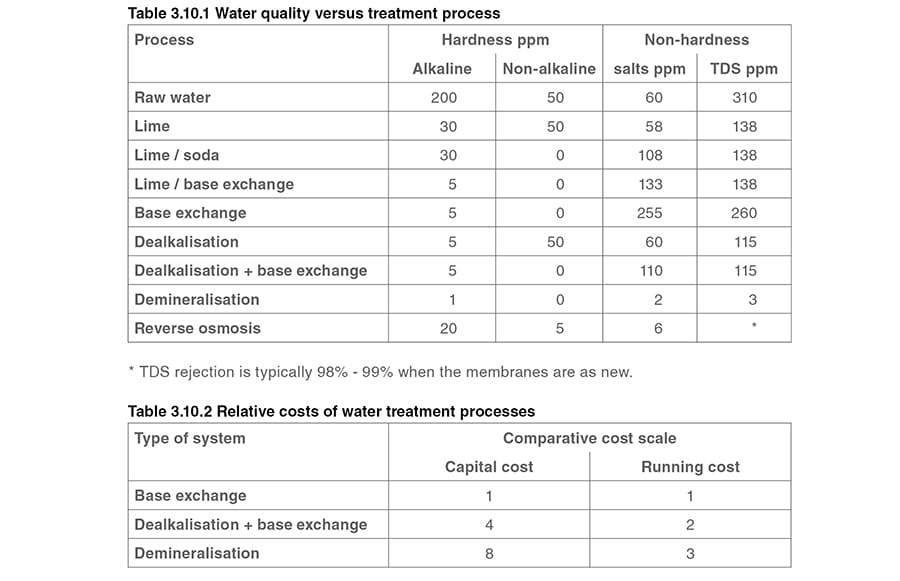

The hardness of water is caused by calcium and magnesium ions which will vary greatly throughout the country depending on the source.

Total alkalinity 600 ppm maximum.

Feedwater hardness usually ranges from 0 01 to 2 0 ppm but even water of this purity does not provide deposit free operation.

In addition hardness salts can precipitate from the boiler water to form sludge and eventually scale which deposits on the internal surfaces of the boiler.

Water treatment recommendations vary depending on the operating pressure of the boiler the application steam or hot water and other parameters.

A low pressure fire tube boiler can usually tolerate high feed water hardness with proper treatment while virtually all impurities must be removed from water used in some modern high pressure boilers.

Feed water purity requirements therefore can vary widely.

Total hardness 0 3 ppm.

A serious loss of boiler efficiency and possibly boiler failure.

Only relatively wide ranges can be given as to maximum levels of alkalis salt silica.

Total hardness 1 ppm maximum.