Brazed plate heat exchanger technology offers significantly higher thermal efficiency than comparable shell and tube models within a much smaller footprint.

Brazed aluminum plate fin heat exchangers.

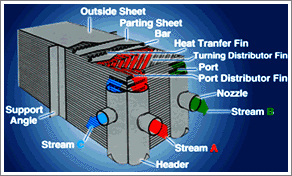

The unit s compact size is due to the heat transfer fins and the aluminum material.

Compact size and versatility are typical features of a brazed aluminum plate fin heat exchanger.

Even so brazed aluminum exchangers are often not considered because of complicated design equations and complex stacking arrangements.

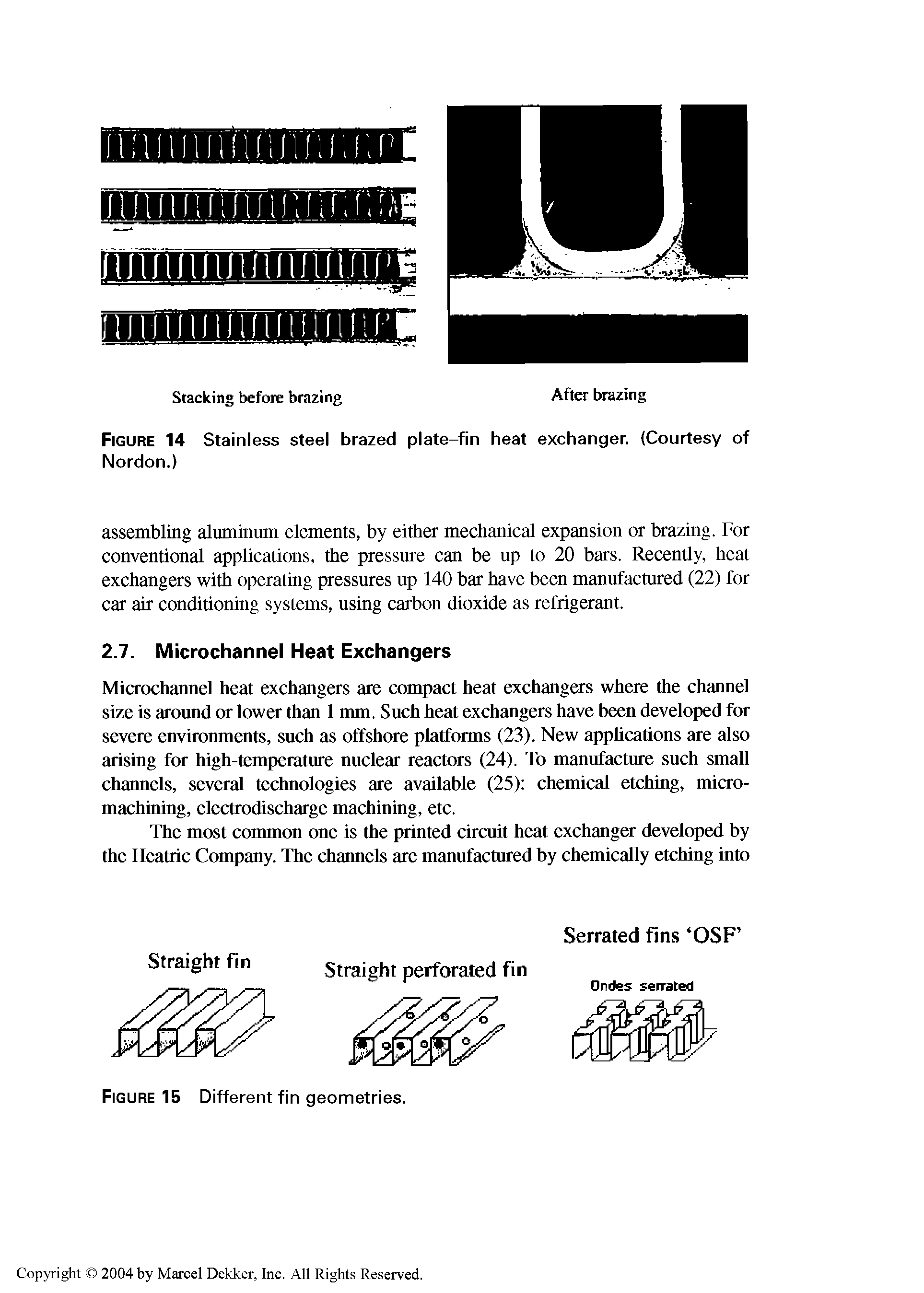

Our heat exchangers composes of corrugated fin and separation plate which are stacked and brazed.

Aluminum alloy plate fin heat exchangers often referred to as brazed aluminum heat exchangers have been used in the aircraft industry for more than 60 years and adopted into the cryogenic air separation industry around the time of the second world war and shortly afterwards into cryogenic processes in chemical plants such as natural gas processing.

Brazed aluminum heat exchangers bahx which are mission critical for a wide variety of cryogenic processing applications where reliability and thermal efficiency are paramount.

Chart s heritage begins with the adaptation of the product from the aerospace industry in the 1950s.

Brazed aluminum heat exchangers have superior heat transfer capabilities and can be cost effective for non corrosive gases and liquids as compared with traditional shell and tube exchangers.

Comparing to the other type of heat exchangers by enlarged heat transfer area this type of heat exchanger becomes more compact and lighter.

Brazed aluminium plate fin heat exchangers are very compact exchangers built to a high specification for use in air separation plants and a wide range of other petrochemical and refrigeration applications.

Ready to take the next step.

Chart s brazed aluminum heat exchangers also known as a plate fin heat exchanger and cold boxes are at the heart of low temperature natural gas air separation and petrochemical processes worldwide.